A Laser Focus on Service

Customer Challenge

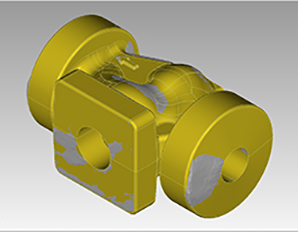

A manufacturer of large fluid handling equipment was moving a suite of valve castings from one foundry into another as part of a strategic initiative to launch a new product. Critical to the process were the rapid transfer of patterns and the launch of new patterns. Timing became compromised during the qualifications phase where internal and external geometries of the new valve castings were being tested. As a result, launch of the new product and realization of the benefits associated with the move were threatened.

Beyond Precision Solution

ACME informed the valve manufacturer that, in addition to being fully capable of machining the valve castings, ACME would be able to create a 3-dimensional digital representation of the new castings using laser scanning technology. By scanning the exterior of a new casting, sectioning the casting and scanning the interior of the two halves and then digitally “stitching together” these three images, ACME was able to create a fully detailed dimensional representation of the sample castings. Furthermore, by digitally overlaying this representation onto a CAD solid model of the part, ACME was able to determine any non-conformances against profile tolerances for each sample part from the new foundry.

Acme Industries’ Value

Working with the valve manufacturer, ACME developed a laser scanning schedule to ensure timely implementation of the critical patterns. With the timetable in place, ACME engineers performed the scanning, sectioning, and data manipulation required to validate the sample castings. The valve manufacturer realized planned improvements to its foundry supply base without delay, and successfully introduced its new products to the marketplace.